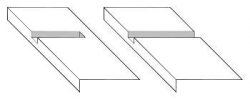

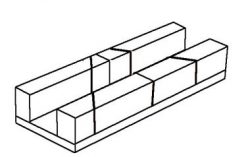

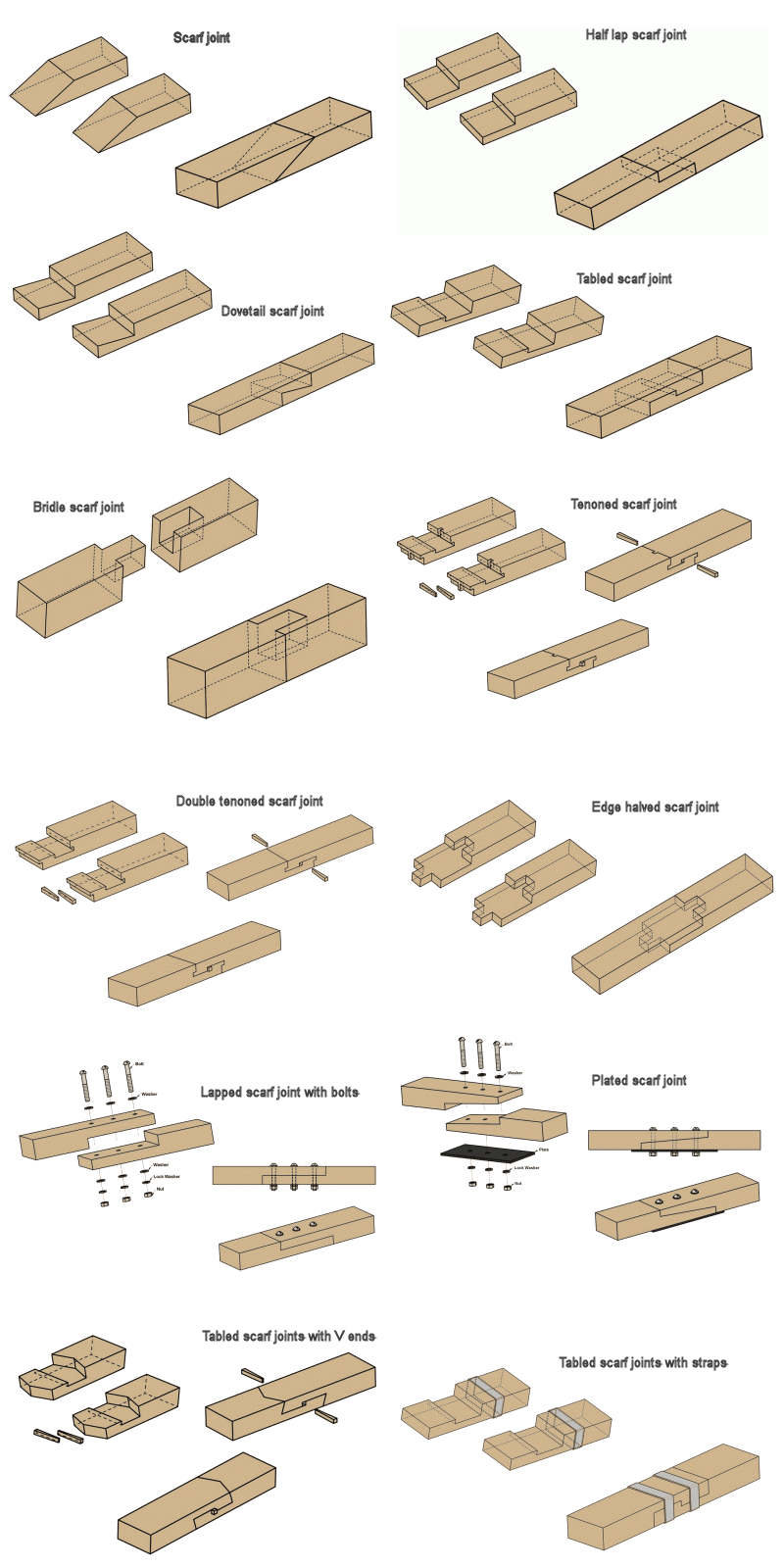

Twelve different scarf joints.

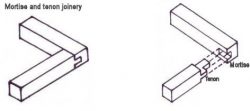

Joinery for boats and woodworking in construction of buildings.

The scarf joint consists of twelve different applications based on the same priciple.

Here are the main types to make and reinforce this joinery method with scarves.

Its main application is for large timber.

Lumber is often not large enough when you have to make a big construction.

Barns and sheds need very large pieces of wood that can only be obtained by elongating the lumber.

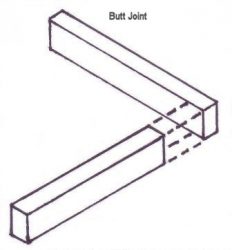

A connection of those wooden beams can be done in several manners.

The scarf joints are among the most used methods for this purpose.

https://www.youtube.com/watch?v=6j-U1P49r8U

These are the main types for a scarf joint.

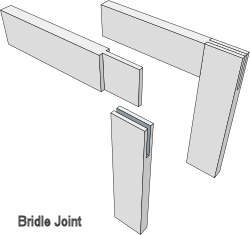

It is a bit more complicated to make the interlocking types compared to plain joints.

The latter are a lot quicker to make, but they are also a lot weaker and less atractive than the interlocking variants.

12 Different ways to make a scarved woodworking joint.

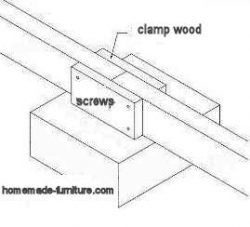

Choose a method which provides sufficient strenth.

This joinery does not have a lot of strength by itself, even though the interlocking types are a bit stronger.

Which of these joinery methods you will use depends firstly on your skills.

Furthermore important is whether the joint will be visible or not.

See on Wikipedia how to calculate the strength for each type of scarf joints.

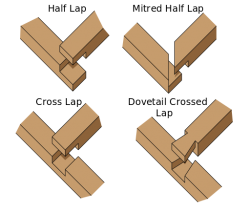

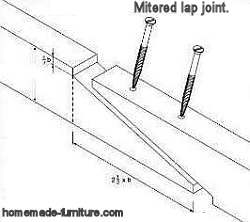

More woodworking techniques and joinery methods.