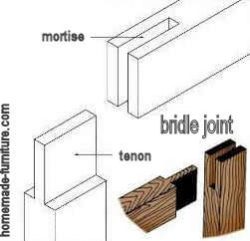

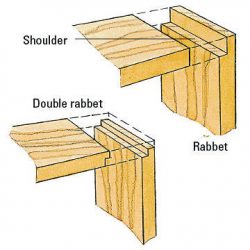

The rabbet joint consists of a shoulder on one or two panels.

For this joinery method the connecting panels we attach the panels in a ninety degrees angle.

It is a simple woodworking technique to make, with many different tools.

You do not have to be a carpentry expert to make these wood joints.

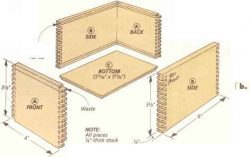

A joint of this type stays usually out of sight.

Its use is mainly for the backside of cabinets, where it makes the joint between back and side panels.

The single shouldered joint only has a groove in one of the panels.

The shoulder is what supports the corresponding piece, it is also called the bearer.

On this picture you see the difference between a single and the double shoulder version for this woodjoint.

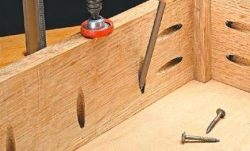

Use glue in combination with thin nails or screws to strengthen this joinery.

Since the joint is usually hidden those pinholes or screw heads will not be seen afterwards.

Rabbet joints can be made with the following tools.

- Mechanically with a router and using a straight or rebate bit.

- Also on a machine, with a rebate plane or a shoulder plane.

- With multiple passes using a circular saw.

- The dado set is perfect to make a rabbet joint in a single pass.

- A spindle moulder is also a good machine to make these grooves.

- By hand with a chisel and hand saw.

- And furthermore you could use a jointer that is equipped with a rabbet ledge.

A rabbet joint made without tools and only using glue.

Two boards are glued together, while leaving a gap at the edge.

Doing so on both panels gives them the right shape to fit together.

For that reason glue and dowels help to keep this joinery together.